Designing and Creating PLC Programs

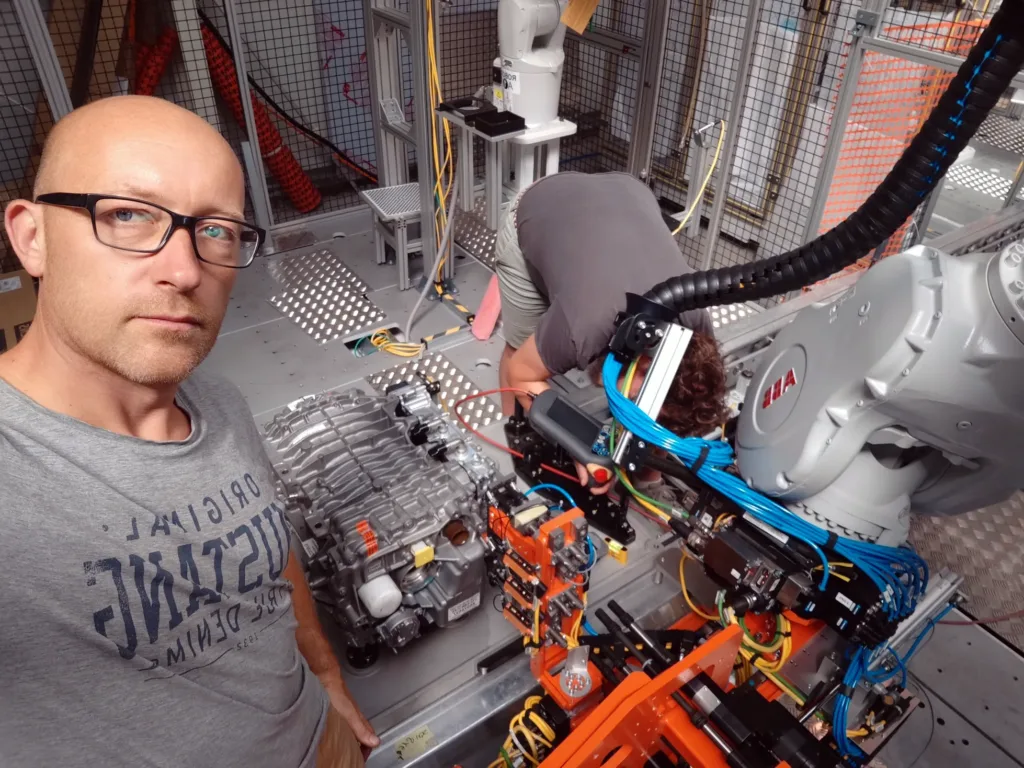

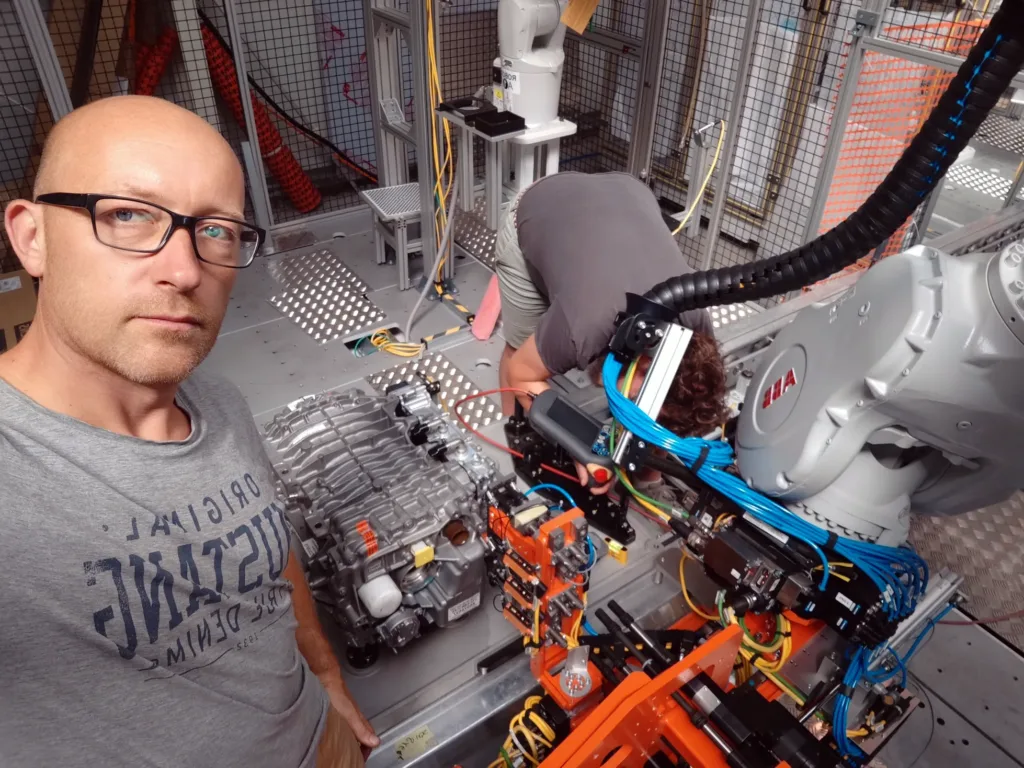

Designing and Creating PLC ProgramsOur team of software engineers possesses the knowledge and experience needed for the design and creation of advanced PLC controller programs. We utilize the latest technologies and programming tools to ensure the optimal functioning of the controllers and to meet the unique requirements of our Clients.

We are developing programs that enable control over production processes, monitoring of parameters, device management, and the execution of complex algorithms, ensuring optimized system performance.

What is the essence of programming PLC controllers?

Ladder Diagram (LD/LAD),

- Function Block Diagram (FBD),

- Structured Text (ST/SCL),

- Sequential Function Chart (SFC/GRAPH),

- Instruction List (IL/STL).

Integration with industrial systems

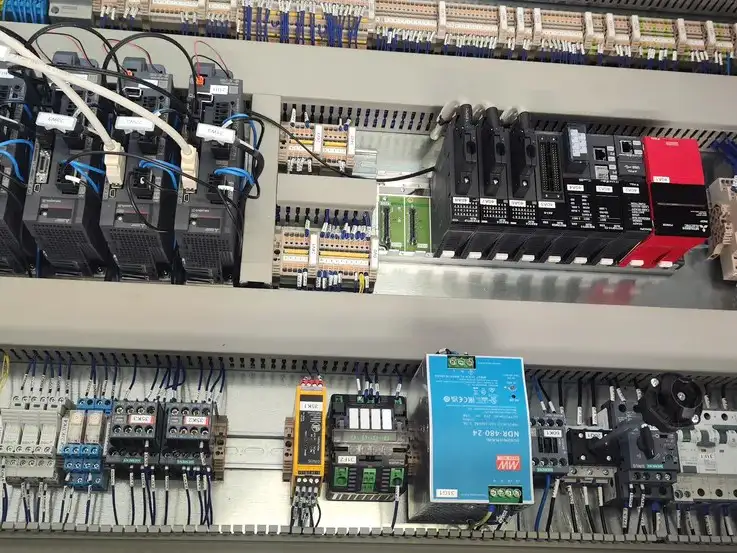

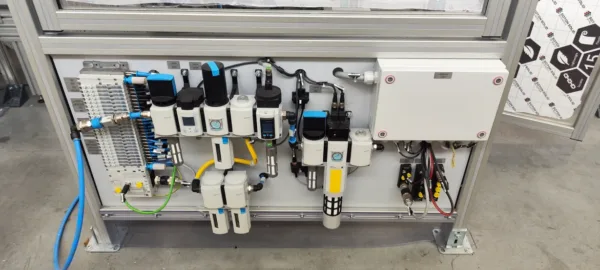

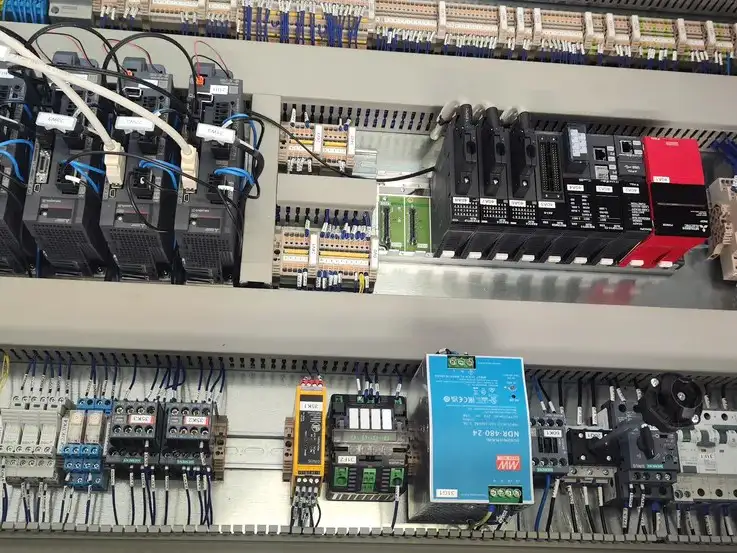

During the programming of PLC controllers, we ensure full integration with existing industrial systems. Our solutions are scalable and compatible with various devices and machines used in the production process. As a result, PLC controllers can cooperate with other system components, such as sensors, motors, drives, and operator panels. Integration ensures the cohesive operation of the entire production system and enables effective collaboration among different elements.

The main benefits of integrating PLC controllers with the production system.

Why is it worth choosing MDP Engineering?

Modern technologies

Individual approach

We tailor solutions to the specific needs and budget of the Client, ensuring optimal results.

Comprehensive service

Testing and optimization

Testing of PLC programs

Optimization of PLC programs

The optimization aims to improve the performance of the controller, shorten the scanning cycle time, reduce memory consumption, and simplify and enhance the readability of the code, thereby facilitating its subsequent maintenance and expansion.

Training and support

We offer training for your staff that will assist them in understanding and operating PLC controllers. Our team is also available to provide technical support and answer any questions related to programming and operating PLC controllers.