MDP Engineering provides comprehensive programming, integration and commissioning of industrial robots — from motion-path programming and logic control to full cell integration and deployment in production environments.

Strategic Approach to Process Automation

Needs Analysis and Solution Design

We begin each project with a detailed technological audit, during which our engineers identify key areas for optimization. We use advanced simulation tools (including Visual Components, RoboDK) to create digital twins of production lines, which allows for precise modeling of production scenarios before physical implementation. As part of our collaboration, we prepare:

- Process maps with an analysis of production bottlenecks.

- A technical and economic report with an ROI forecast.

- An implementation schedule that accounts for the client’s production cycle.

Industrial Robot Programming

Our expertise covers the full scope of programming:

- Six-axis robots (KUKA, ABB, Fanuc) for welding, assembly, and handling tasks.

- Cobots (Universal Robots, Techman) for collaboration with operators in safety zones.

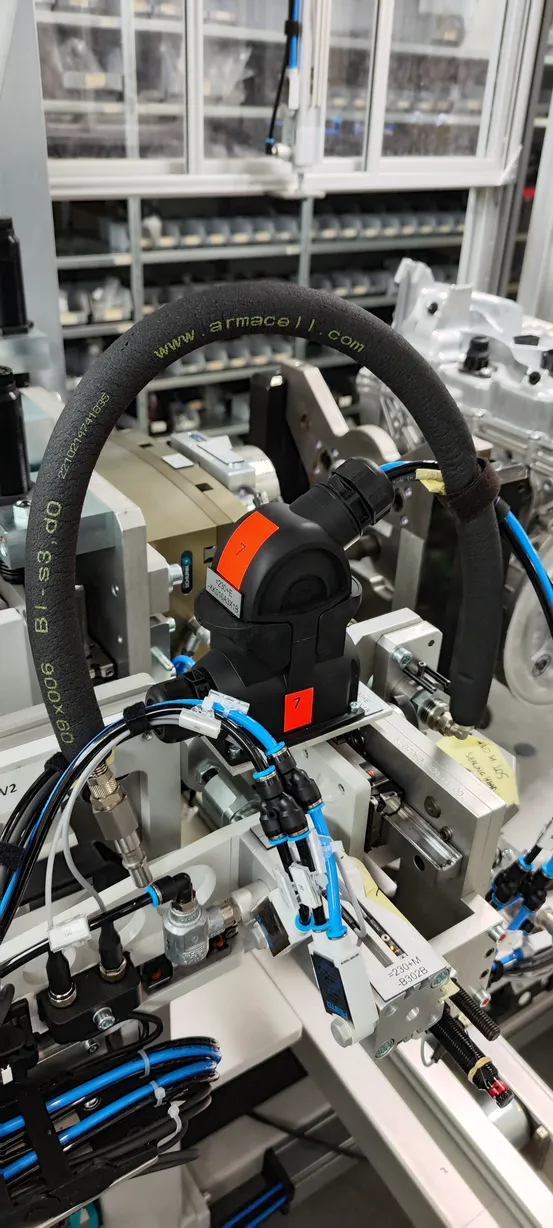

- Vision systems (Cognex, Keyence) integrated with control systems.

- Specialized applications (grinding, packaging, palletizing).

Example implementations include programming motion trajectories with geometric deviation compensation ( mm) and implementing AI algorithms for adaptive process control.

Architecture of Technological Connections

We carry out the comprehensive integration of robots with:

- CNC machines (MTConnect, OPC UA protocols).

- MES/ERP systems (API interfaces, Web Services).

- IoT devices (IO-Link sensors, measurement systems).

- Safety infrastructure (light curtains, pressure-sensitive mats).

Industrial System Integration:

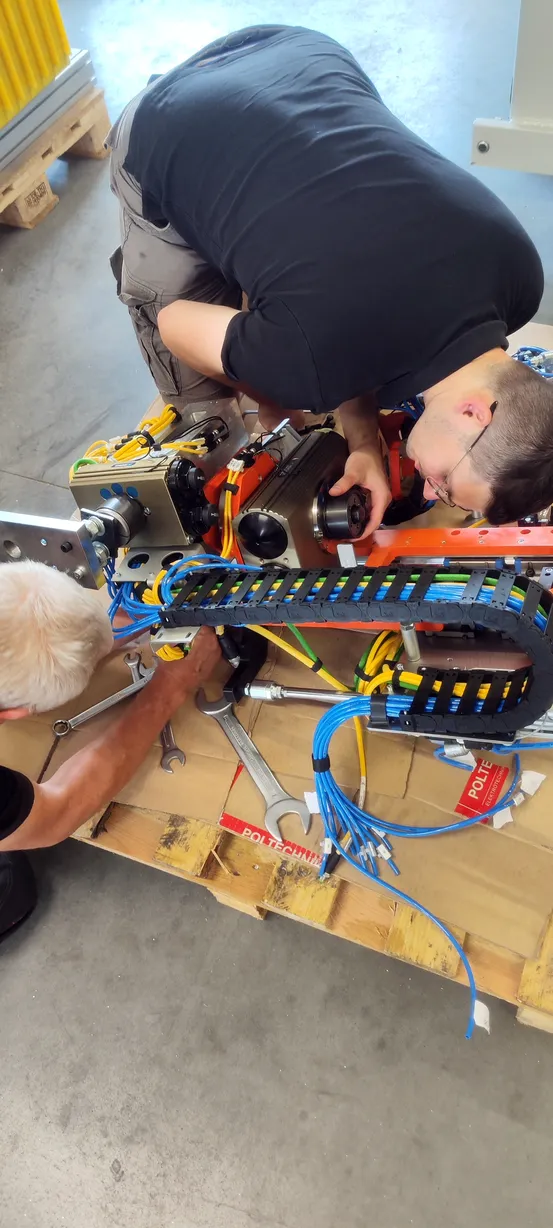

During robot programming and commissioning, we ensure full integration with existing production systems. Our experts in automation and robotics can effectively connect robots with other devices and machines in the factory, ensuring a smooth flow of data and synchronization of operations. This makes it possible to create a comprehensive and integrated system that works harmoniously and efficiently.

When modernizing existing production lines, we use a modular integration approach that minimizes technological downtime to 48 hours.

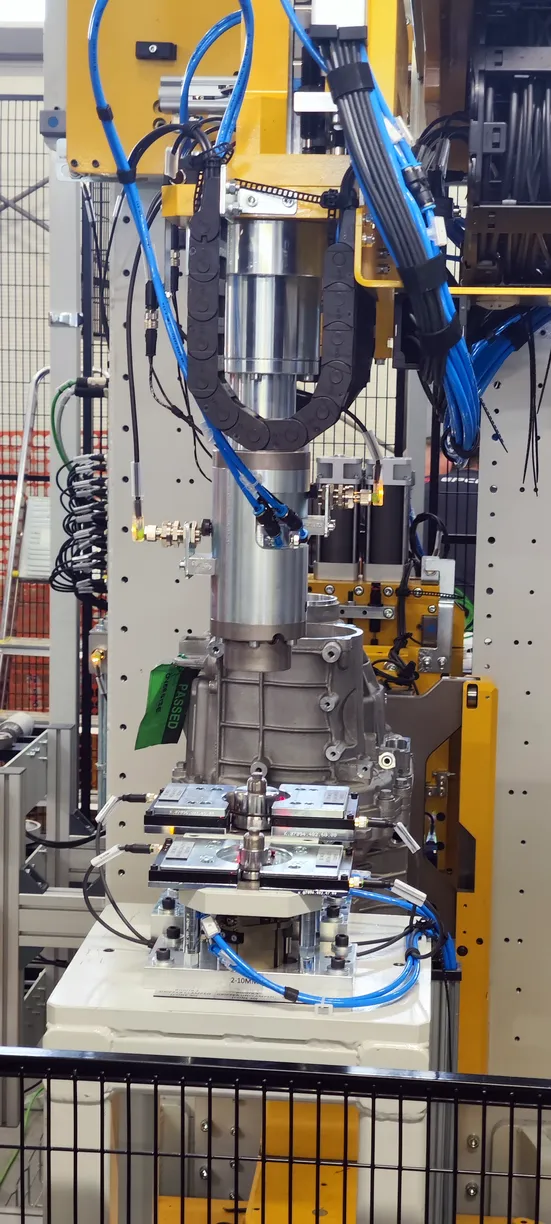

Commissioning Process and System Validation:

Our service also includes full robot commissioning in the production environment and optimization of their operation. Our engineers conduct tests, configure robot parameters, and adapt their operation to the specifics of the client’s production. We work with the client’s team to ensure full satisfaction and the achievement of optimal results. Additionally, we offer training and technical support so that our clients can independently manage the robots and maintain their high performance.

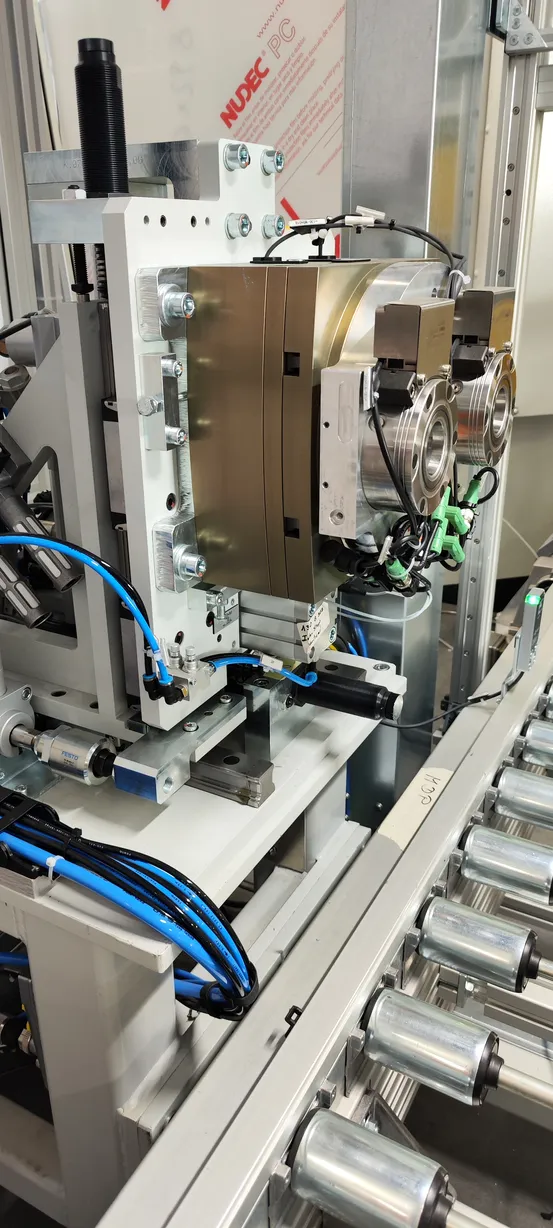

Factory Acceptance Testing (FAT)

We conduct comprehensive functional tests in a controlled environment:

- Validation of the production cycle with a simulation of real conditions.

- Stress tests (120% of nominal capacity).

- Vibration and thermal imaging analysis of the execution systems.

Site Acceptance Test (SAT)

Our technicians provide:

- Mechanical assembly with laser measurements of positioning.

- Tool calibration (TCP, tool center point).

- Operator training with competency certification.

Monitoring Systems and Predictive Maintenance

We implement advanced IIoT solutions for remote supervision:

- MDP SmartFactory platform with production dashboards.

- Predictive algorithms for forecasting failures (LSTM networks).

- OEE reports (Overall Equipment Effectiveness) in real-time.

Clients receive access to a portal with historical data and tools for trend analysis.

After-Sales Support and System Development

We offer training for your staff to help them operate and program the robots. Our team is also available to provide technical support, answer questions, and help solve any problems.

Collaboration Models

- Technical subscription with an 8/5/24 response time guarantee.

- Modernization programs (5-year technological roadmaps).

- Periodic audits with optimization of process parameters.

Our service center, equipped with testing stations, enables quick diagnosis of components (average repair time: 3.5 hours).

MDP Engineering specializes in programming and implementing advanced industrial robots, tailored to diverse tasks along production lines. Supported solutions include six-axis robots from leading manufacturers such as KUKA, ABB, and Fanuc, ideal for welding, assembly, and parts transport. We also deliver projects involving collaborative robots—cobots from Universal Robots and Techman—designed for safe cooperation with human operators. Our systems integrate sophisticated vision technologies and realize specialized applications, such as grinding, packaging, and palletizing, customized to the specific needs of various industries.

Key robot types and applications:

Six-axis robots (KUKA, ABB, Fanuc): welding, assembly, transport

Cobots (Universal Robots, Techman): human-robot collaboration

Integrated vision systems

Specialist applications: grinding, packaging, palletizing

The programming and commissioning process consists of several key steps to ensure seamless integration with the production line. We start with a technological audit and accurate process modeling using advanced tools such as Visual Components or RoboDK to create a digital twin of the line. Next, we optimize and configure the robot’s motion trajectories, applying geometric deviation compensation for accuracy up to ±0.05 mm. We also implement AI algorithms that enable adaptive control of the robot under changing conditions. The process concludes with comprehensive FAT (Factory Acceptance Test) and SAT (Site Acceptance Test) procedures, assuring quality and operational safety.

Key process steps:

Technological process audit

Modeling and simulation in a digital environment (e.g. Visual Components, RoboDK)

Trajectory configuration and geometric deviation compensation (accuracy up to ±0.05 mm)

Implementation of AI algorithms for adaptive control

FAT/SAT testing and final acceptance

When modernizing production lines, minimizing downtime is crucial to maintain production continuity and reduce losses. We use a modular integration approach, allowing most new components and systems to be prepared in advance before on-site installation. This ensures that assembly and start-up proceed smoothly, reducing technological breaks to as little as 48 hours, especially in system upgrades or expansions. We also cooperate closely with the client’s maintenance team to accurately plan the schedule for work and implementation.

Key solutions:

Modular integration approach

Preparation of systems offline

Downtime reduction to as little as 48 hours

Close cooperation and scheduling with the client

After the implementation of a robot, we offer comprehensive service and modernization support tailored to each client’s needs. We carry out modernization programs such as five-year technology roadmaps, covering planned hardware and software upgrades. Regular technical audits are conducted to monitor system performance and identify areas for optimization. Our team responds quickly to service requests—average repair time for components is about 3.5 hours. Every client receives access to detailed technical reports and recommendations, enabling continuous and safe development of automation at their facility.

Key elements of cooperation:

Modernization programs & technology roadmaps

Periodic technical audits

Fast service response and repairs

Access to reports and automation recommendations