Production Automation & Turnkey System Implementation

MDP Engineering delivers advanced production-line automation solutions designed to optimise industrial processes, increase throughput and enhance precision across manufacturing operations.

What can we do for you?

We develop the concept of a machine or production line according to the Client’s requirements. We create 3D models, machine designs, technical drawings, and documentation. We use only materials from verified suppliers. The production lines designed by us comply with the required regulations and standards, and we have many years of experience in the industry.

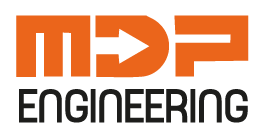

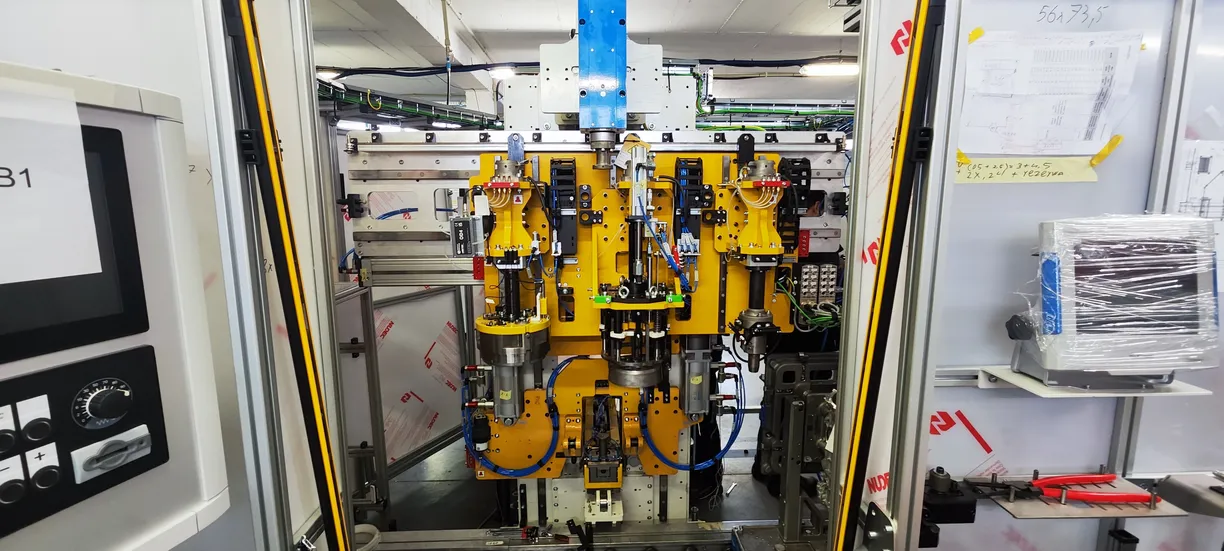

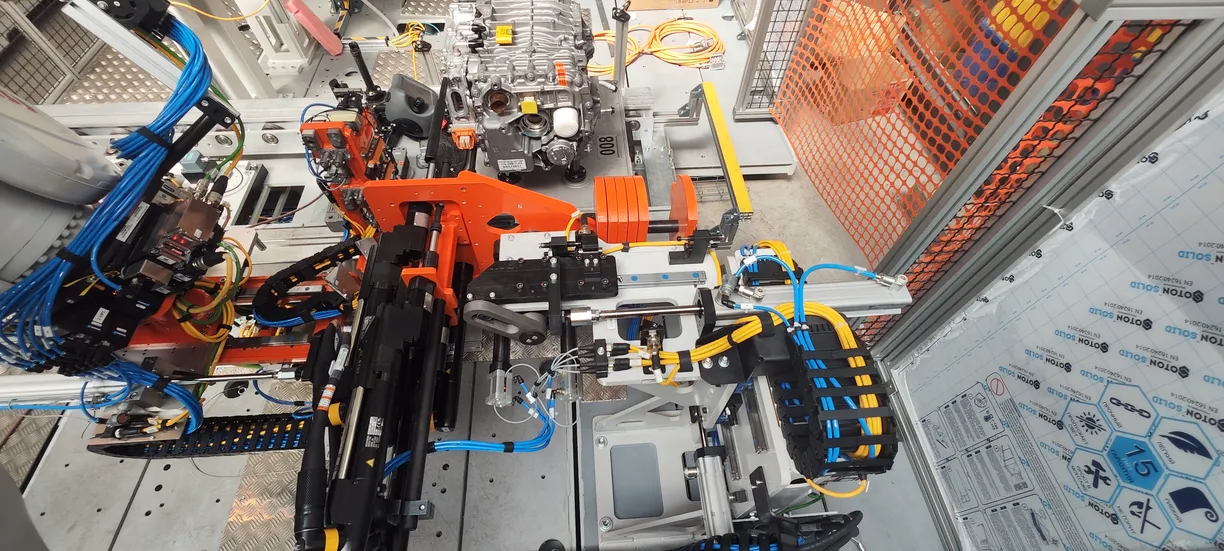

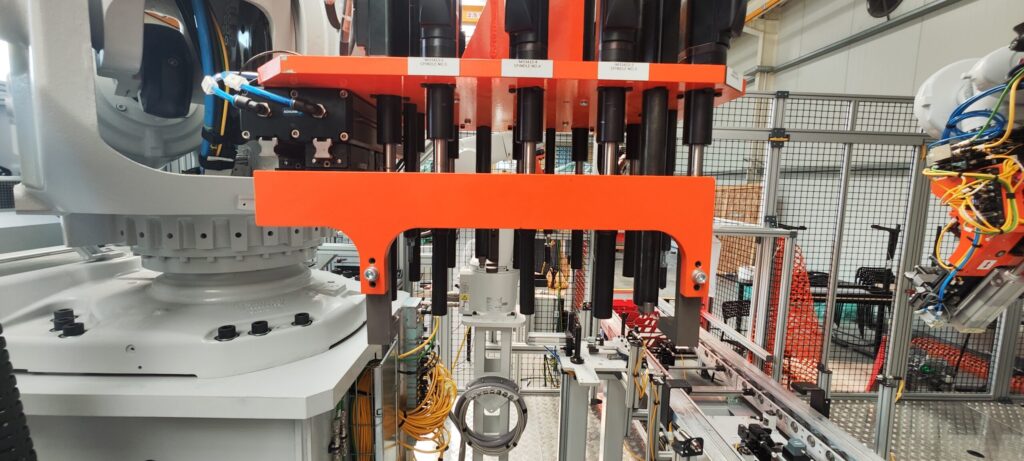

Automated production robots enable the execution of complex processes on the production line in a short time. We have experts in robotics and machine construction who combine their knowledge to implement robotic workstation solutions for our clients.

MDP Engineering implements various types of production lines tailored to industry-specific needs and technological processes. We design assembly, packaging, testing, sorting, and processing lines, integrating automation, robotics, and PLC control systems. Each project is built with a focus on maximum efficiency, safety, and precision.

- Assembly, packaging, and labeling lines

- Testing, sorting, and inspection lines

- Processing lines for different industries

- Integration of automation, robotics, and PLC systems

- Design optimized for efficiency and safety

Yes, MDP Engineering delivers fully customized projects tailored to the specific processes and requirements of each client. Every solution is developed from the ground up — from concept and 3D design to implementation, commissioning, and integration with existing systems. This approach ensures maximum efficiency and functionality within the production environment.

- Custom-designed projects based on client requirements

- Complete process: design, implementation, commissioning

- Integration with existing lines and control systems

- Optimization for efficiency and ergonomics

Yes, MDP Engineering performs modernization and automation of existing production lines, adapting them to current technological and safety standards. We analyze the condition of the installation, develop an upgrade concept, and integrate new control and robotics systems. As a result, the line achieves higher efficiency, reliability, and flexibility.

- Audit and analysis of the existing installation

- Modernization of control and automation systems

- Integration of PLC, HMI, and industrial robots

- Improved efficiency, safety, and precision

Production automation increases process efficiency, reduces human error, and enhances product quality and consistency. It also enables better resource utilization, cost optimization, and improved workplace safety. This investment translates directly into a stronger competitive advantage for the company.

- Higher efficiency and process repeatability

- Reduced errors and operational costs

- Improved quality and safety

- Optimized use of resources and production time

- Enhanced competitiveness of the business

Cooperation with MDP Engineering starts with an initial contact and discussion of project needs or technical challenges. We then perform a feasibility analysis and prepare a solution concept along with a detailed quotation. After approval, we proceed with design and project implementation.

- Initial meeting or technical consultation

- Needs analysis and feasibility assessment

- Preparation of solution concept and quotation

- Project implementation after approval

Yes, MDP Engineering provides detailed quotations and technical audits for planned or existing installations. We analyze the technical condition of equipment, process efficiency, and possibilities for modernization or expansion. Our assessments help define project scope, cost, and potential benefits with precision.

- Detailed quotation for investment or modernization projects

- Technical audit of production lines, machines, and control systems

- Assessment of process efficiency and safety

- Optimization and cost-saving recommendations