MDP Engineering provides bespoke mechanical-design services spanning full 2D and 3D CAD/CAE workflows. Using industry-standard CAD platforms such as Siemens NX, SolidWorks and Autodesk Inventor, our engineers deliver precision-engineered models and documentation tailored to clients’ technical and industrial requirements. Our approach ensures accuracy, manufacturability and adherence to relevant standards across diverse industrial sectors.

3D CAD Modelling & Digital Engineering

We employ advanced CAD/CAE tools to generate detailed, manufacturable 3D models. These models undergo geometric validation, tolerance specification and are prepared for downstream processes including strength analysis, prototyping and production integration.

3D model design is the process of creating three-dimensional digital representations of objects that can be used in various industries, from engineering and manufacturing to architecture and design. 3D models allow for visualization, analysis, and preparation for production, which significantly streamlines the entire project implementation process.

- We create advanced, three-dimensional models using NX, SolidWorks, and Inventor.

- 3D models allow for detailed visualization and analysis of the project from different perspectives.

- We ensure the highest quality and compliance with technical requirements.

- Our models facilitate product optimization and speed up the production process.

Precise 2D Technical Drawings:

Precise 2D technical drawings are the foundation of professional design and production. At MDP Engineering, we use advanced 2D CAD tools to provide our clients with documentation of the highest quality, meeting all technical requirements and industry standards.

Integration with 3D Models:

Modern CAD programs allow for the creation of 2D drawings directly from 3D models, which enables the automatic updating of documentation with every change made to the model. This eliminates errors resulting from data inconsistencies and speeds up the documentation preparation process.

Benefits of Using Precise 2D Technical Drawings

Design Communication: Enables unambiguous information transfer between designers, engineers, and contractors.

Production Optimization: Precise dimensions and tolerances minimize errors and improve execution quality.

Quick Changes: The digital format makes it easy to update documentation if the design is modified.

Versatility: 2D drawings are universally understood and used in most technical industries.

Optimization and Strength Analysis:

At MDP Engineering, we use modern tools for strength analysis and optimization, such as FEM simulations and optimization algorithms. This allows us to provide clients with solutions that are not only precisely designed but also optimized for cost and durability, which translates into real savings and safety in use.

- We conduct simulations of loads, material strength, dynamics, and heat flow.

- Analyses allow for the assessment of project durability and efficiency.

- Through optimization, we increase the safety and functionality of the final product.

Benefits of Optimization and Strength Analysis

- Cost Reduction: Less material consumption and reduced production time.

- Increased Safety: The design is adapted to real loads and operating conditions.

- Improved Functionality: The optimization of shapes and dimensions leads to better functional properties.

- Shorter Lead Time: The automation of optimization processes accelerates design.

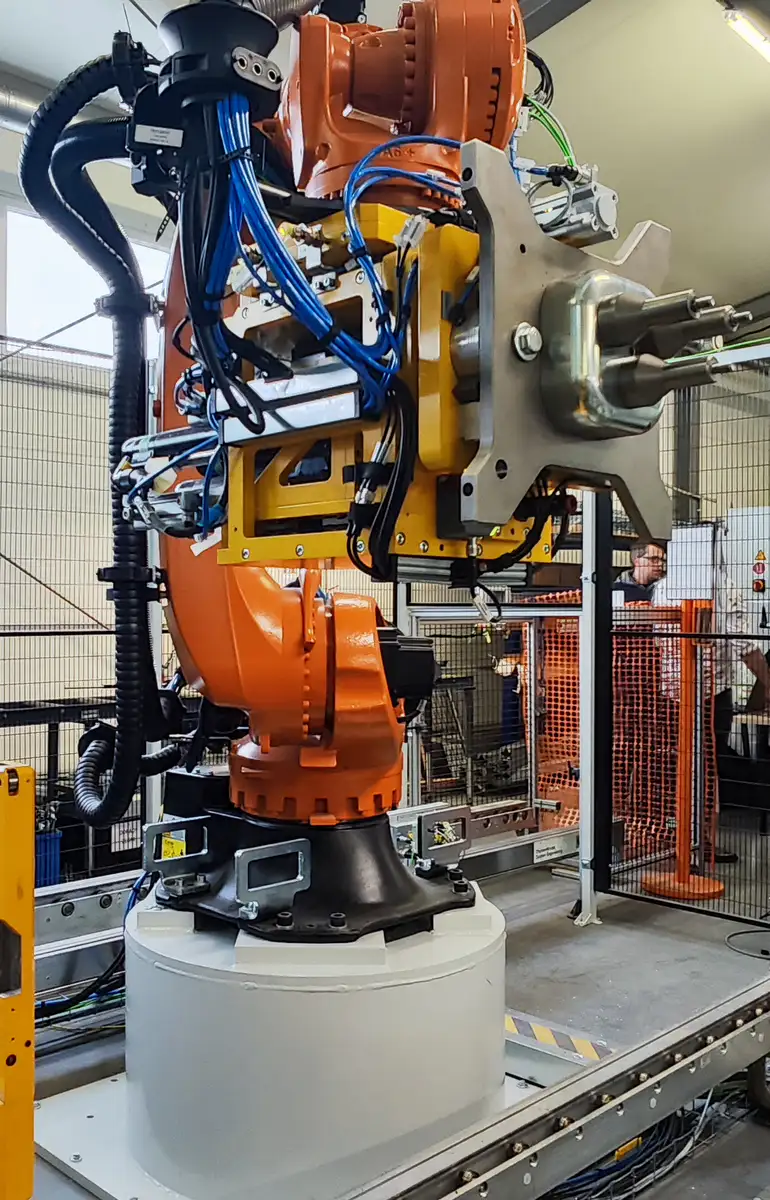

MDP Engineering supports a wide range of industrial sectors where production line and automation system design in 2D and 3D is essential. We develop solutions for automotive, food, pharmaceutical, and processing industries. Each project is carefully tailored to the specific technological environment.

- Automotive industry and component manufacturing

- Food and pharmaceutical industry

- Packaging and processing lines

- Automation and robotics systems

The integration of 2D drawings with 3D models involves combining traditional technical drawings with three-dimensional spatial models to provide a more complete project representation. This allows for early detection of design errors and collisions and enables better planning of the assembly process. Such integration improves accuracy and efficiency during both the design and production stages.

Key points:

- Synchronization of 2D drawings with 3D models

- Elimination of design errors and collisions

- Improved planning of assembly and production

To start a project, the client should provide key details regarding technological requirements and expected parameters of the production line. It is also important to define the available installation space, types of products, and desired level of automation. The more precise the initial data, the smoother the design and implementation process will be.

- Technological and production specifications

- Dimensions and layout of the installation site

- Expected degree of automation and robotics

- Product and production process data

MDP Engineering prepares detailed technical documentation required for both production and assembly of industrial equipment and production lines. This includes construction drawings, electrical and pneumatic diagrams, and assembly instructions prepared in compliance with current standards. Our documentation ensures a seamless transition from the design phase to commissioning, guaranteeing top quality and safety.

- Comprehensive production and assembly documentation

- Electrical, pneumatic, and mechanical schematics

- Assembly instructions compliant with quality and safety standards

Utilizing advanced 3D and 2D designs at MDP Engineering provides full visualization of workstations and precision at every project stage. 3D modeling enables rapid collision detection, ergonomic optimization, and streamlined integration with existing production systems. 2D designs ensure precise technical documentation, accelerating assembly, manufacturing, and future maintenance of machines. This approach minimizes errors and enables smooth communication between design, implementation teams, and the client.

Key benefits of 3D/2D design use:

Fast visualization and collision detection

Ergonomic and integration process optimization

Precise technical documentation

Streamlined assembly, production, and service

Error minimization and smooth communication

Yes, MDP Engineering specializes in delivering custom projects tailored to specific client needs and requirements. The design process begins with a detailed analysis of the task and technical consultations, allowing us to propose innovative solutions and adapt technologies to production conditions and budget constraints. The flexibility of our team and broad engineering expertise enable us to implement non-standard concepts—even in niche industries and demanding applications.

Key aspects of custom projects:

Detailed analysis of needs and requirements

Technical consultations and solution personalization

Implementation of unique and innovative concepts

Technology selection matched to client’s conditions and budget