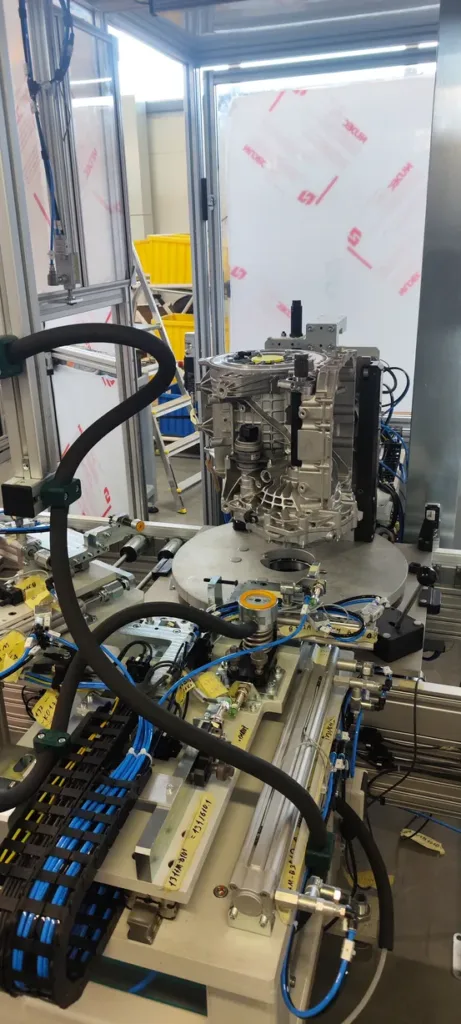

MDP Engineering delivers custom end-to-end engineering solutions — from conceptual design through mechanical fabrication, automation integration and full system commissioning — for bespoke machines, assembly lines and production systems tailored to clients’ specific requirements.

Design and construction of machines, assembly lines, and production facilities:

Our team of experienced engineers, mechanics, and automation specialists designs a wide range of specialized machines using modern CAD software and simulation methods to create structures optimized for functionality, durability, and safety.

We offer design services for:

- Material processing and handling machines

- Transport and manipulation equipment

- Testing and inspection stations

- Packaging and labeling machines

- Other custom-purpose machinery

Each project begins with a detailed analysis of the client’s needs and complies with applicable standards and regulations.

Reliability, flexibility, adaptation to the needs of the Client.

MDP Engineering designs a wide range of industrial machines customized to meet specific client requirements. This includes equipment for material processing, transport and handling, testing and inspection, as well as packaging and labeling. Each design is created with a focus on process efficiency, safety, and long-term reliability.

- Material processing and handling machines

- Transport and positioning systems

- Testing and inspection stations

- Packaging, labeling, and assembly equipment

- Solutions customized for specific production processes

MDP Engineering ensures the safety of machines and production lines by designing according to current standards and implementing certified safety systems. We perform risk assessments, integrate safety control systems, and program PLCs to meet required safety categories. Our priority is to protect operators and guarantee reliable operation of the entire system.

- Risk assessment and compliance with PN-EN ISO 13849 and IEC 62061 standards

- Integration of safety systems within PLC control

- Installation of protective devices – light curtains, barriers, emergency stops

- Testing and verification of safety functionality

Yes, MDP Engineering designs and delivers turnkey production lines, covering the entire process — from concept and design to installation, commissioning, and staff training. This allows the client to receive a fully integrated, ready-to-operate production solution. Our team ensures consistency and quality throughout every stage of project execution.

- Comprehensive delivery from design to commissioning

- Installation, testing, and staff training

- Full integration of automation, mechanics, and control

- Complete responsibility for the implementation process

Yes, the client actively participates in testing and final acceptance of the production line. This process allows for joint verification of system performance, confirmation of compliance with project requirements, and implementation of any adjustments before full commissioning. This approach ensures top quality and customer satisfaction.

- Client participation in FAT and SAT tests

- Verification of compliance with project assumptions

- Opportunity for adjustments during acceptance stage

- Guaranteed quality and system functionality

Yes, MDP Engineering supports clients in optimizing existing production lines, focusing on improving efficiency, safety, and system reliability. We analyze processes, modernize PLC systems and software, and implement solutions to enhance time and energy performance. Our goal is to maximize the potential of the existing manufacturing infrastructure.

- Analysis and audit of existing production lines

- Modernization of control and software systems

- Increased process efficiency and stability

- Optimization of cycle time and energy usage

W MDP Engineering przez lata wypracowaliśmy dobre praktyki budowy maszyn i linii produkcyjnych:

Safety first:

Designing machines with an emphasis on safety is paramount to ensuring a safe work environment. A risk assessment should be conducted in accordance with the PN EN ISO 12100 standard.

Analysis of client requirements:

Before starting the project, a thorough analysis of the Client’s requirements and technical specifications should be conducted. This helps avoid issues at later stages.

Maintenance and control:

The plant infrastructure must be properly designed, maintained, and regularly inspected. It is important that the technical condition of the machines raises no concerns.

Design with safety in mind:

Creating an industrial machine design that incorporates safety systems.

Selection of appropriate materials:

Choosing the right construction materials and components is crucial for achieving an efficient and durable structure.

Prototyping and testing:

Creating prototypes and testing their functionality allows for the detection of potential errors and their correction before implementing the final product.

Iterative AGILE approach:

An iterative AGILE approach in prototype testing enables continuous improvement and technology development.

Standards and norms:

Designed machines must be safe to use and meet safety standards as well as industry norms.

Collaboration with the Client:

Active Client participation in the testing process (FAT and SAT) allows for early detection of potential issues and adaptation of the machine to user needs.

Documentation:

Creating clear and understandable technical documentation for machine users, including operating instructions.

Staff training:

Training the workforce to operate the workstation.

Experienced designers and automation specialists:

We combine a design office with actual machine building. From design, through production, to commissioning.

Implementation of Production Line – Key Stages:

Implementing a production line is a complex process that requires a systematic approach and close collaboration between the investor and specialists.

Below are the most important stages of this process:

1. Concept and Planning

- Analysis of client needs and expectations: Detailed determination of client needs and the specifics of the production plant. Consultations allow for the development of detailed requirements for the technological process.

- Definition of line functionality: Discussions on the functionality of the new production line, aimed at understanding the investor’s expectations. Engineers inquire about details and present available solutions.

- Conceptual design: Development of a general vision and detailed project strategy. Consideration should be given to the most convenient machine layout, work ergonomics, and production needs.

- User specification: Definition of activities to be performed in the plant during production and their sequence.

- Device selection: Placement of machines on the line, selection of measurement apparatus, control systems, and wiring.

- Determination of number of employees: Establishing the optimal number of employees to operate the line, taking into account work safety.

- Analysis of processes in the enterprise: Defining activities to be performed and their sequence.

4. Startup and Testing

- Machine startup: Finalizing mechanical settings, starting control systems, and conducting production tests. Startup should occur in the presence of personnel with appropriate competencies.

- Testing: Testing every functionality of the production line.

5. Implementation and Optimization

- Handover of documentation: Providing necessary documentation and conducting staff training.

- Assembly at the Client: Transporting the line to the Client’s production hall. Refining details and fine-tuning elements.

6. Usage

- Integration and Control: Integration of machines and devices, controlling them through a central system.

- Monitoring and Reporting: Implementing monitoring and reporting systems.

- Continuous Improvement: Ongoing control over the production process and quick response to issues.

- Automation of Transport: Automatic transport between stations using conveyors, robots, or other systems.

- Training and Support: Ensuring proper preparation of employees, training, and technical support.