Our approach to robotic-workstation construction follows a structured, multi-phase engineering process — from conceptual layout to mechanical design, integration, programming, and full commissioning — ensuring reliable, safe and high-performance automation cells.

The Highest Form of Production Process Automation

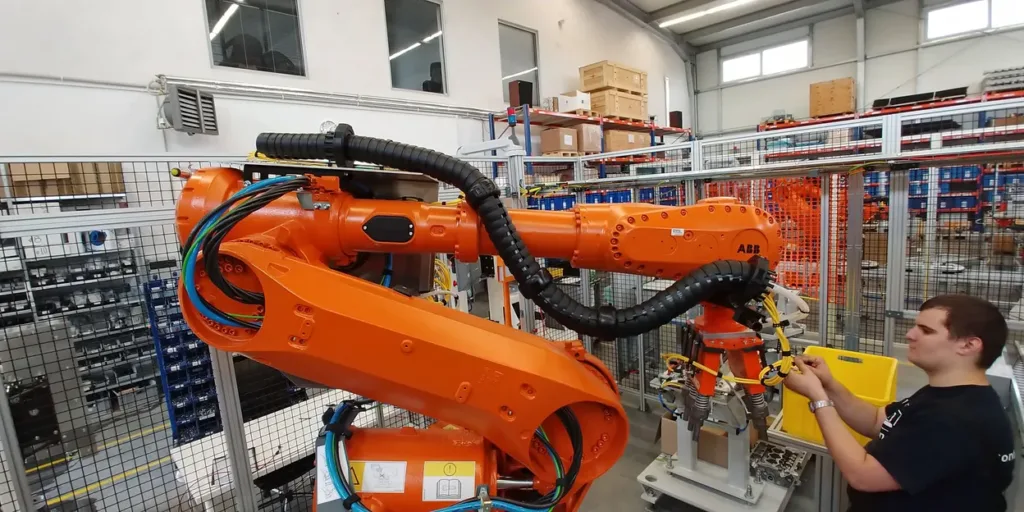

Robotic workstations represent the highest form of production process automation, where appropriately programmed robotic arms can weld, cut, or pack significantly faster and more consistently than humans. These integrated systems are widely used in various industries, including automotive, electronics, food, and pharmaceutical sectors.

In the context of building production lines, robotic workstations are key components that determine the efficiency of the entire manufacturing process.

Characteristics of Robotic Workstations in Modern Production:

Precision of Execution

The robotization of workstations should be precisely tailored to the specifics of the tasks performed and integrated with systems already implemented in the enterprise.

MDP Engineering uses high-quality materials and components, enabling our designed robots to operate in diverse environmental conditions.

Applications in Various Technological Processes

Robotic workstations are used to automate key technological processes, including welding, bonding, painting, transportation, and palletizing.

They are particularly valuable for operations requiring high precision, where tasks performed by workers may be time-consuming and imprecise.

Components and entire assemblies of small parts used in specific technological processes often have highly complex shapes, sizes, and formats, making automation essential for achieving the required quality.

Benefits of Implementing Robotic Workstations

The robotization of production processes is an investment that pays off for many years, enabling business development and the ability to take on additional orders. Improved quality and higher efficiency allow companies to increase competitiveness in the market and optimize the use of human resources.

High accuracy

Flexibility

Production efficiency

Lower costs

Design Stage Using Advanced Tools

MDP Engineering designs workstations with future client needs in mind, considering system expansion and modification possibilities.

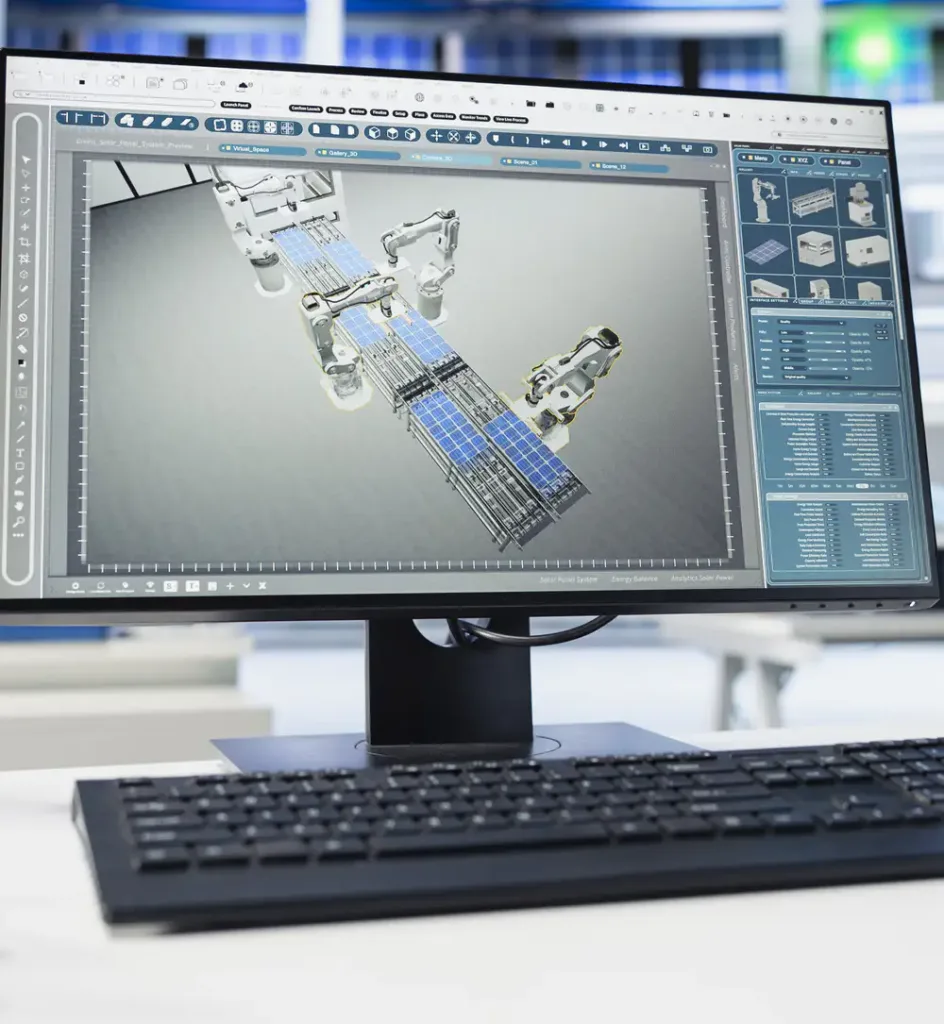

3D Modeling and Process Simulations

The use of CAD software (e.g., SolidWorks) and dedicated robotic simulation tools (ABB RobotStudio, Fanuc ROBOGUIDE) enables the creation of virtual prototypes. In the case of a workstation for milling aerospace components, simulation revealed the need to increase the rotary table’s stiffness by 40%, leading to a design modification using S355J2 steel instead of 6061 aluminum.

Modeling in RobotStudio includes:

Verification of the robot’s reach relative to component dimensions,

Collision analysis across the full range of motion,

Optimization of motion paths, reducing cycle time by 12-18%,

Selection of end tools (e.g., vacuum grippers vs. pneumatic grippers).

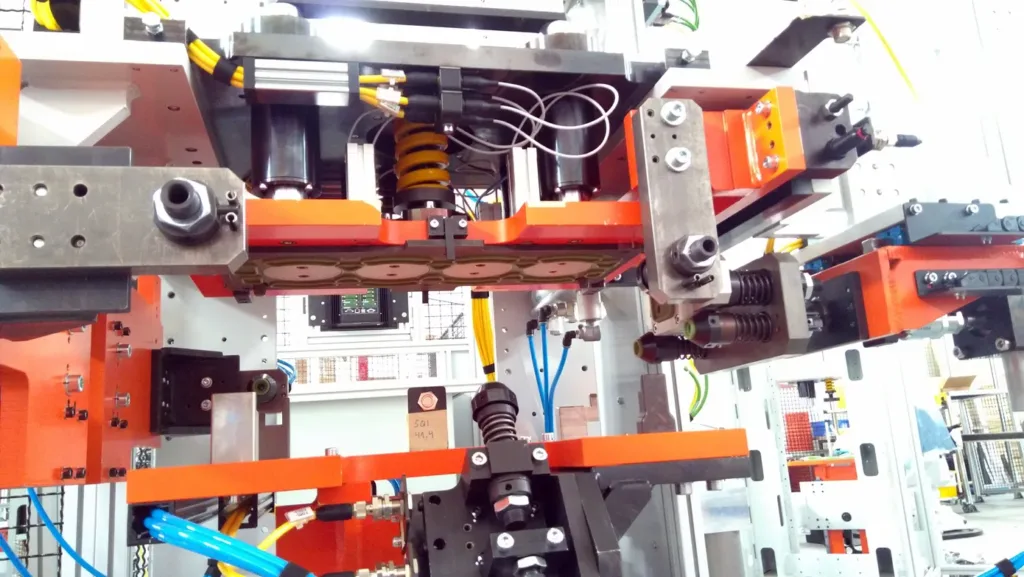

Selection of Components for Precision and Durability

MDP Engineering specialists select components based on:

Required positioning accuracy (e.g., ±0.02 mm for laser marking applications),

Dynamic load (tool moment of inertia),

Operating environment (IP67 rating for wet areas),

Mean time between failures (MTBF above 50,000 hours).

System Implementation and Validation

The prototype phase includes:

Construction of a 1:1 scale test workstation,

Verification of compliance with PN-EN ISO 10218-1/-2 standards,

Measurement of performance parameters (e.g., cycle time, repeatability),

Endurance tests (e.g., 72-hour continuous operation mode).

In a project for an electronics manufacturer, FAT (Factory Acceptance Test) revealed the need to change the conveyor guide material from aluminum to stainless steel, increasing the component’s lifespan by 300%.

Integration with Higher-Level Systems

MDP Engineering workstations integrate with:

MES (Manufacturing Execution System) via the OPC UA interface,

SQL databases for tracking process parameters,

Industrial cloud for predictive maintenance.

Example Communication Architecture:

MDP Engineering designs and implements workstations for a wide range of technological processes that can be robotized efficiently. We provide installations and automation for tasks such as welding, spot welding, painting, transport, and palletizing of products, as well as precise milling, assembling, and picking operations. Our systems are scalable and can be tailored to specific industry requirements—from automotive, through food and beverage, to electronics and pharmaceuticals—allowing for maximum efficiency while meeting strict quality standards.

Key technological processes:

Robotic welding and spot welding

Automated painting and transport

Palletizing and assembly operations

CNC milling

Industries: automotive, food, electronics, pharmaceutical

The construction process of a robotic workstation follows proven stages to ensure high quality and safety. It begins with detailed 3D modeling and process simulations using tools such as SolidWorks or ABB RobotStudio. Motion paths are optimized, and end-of-arm tooling is configured to suit production specifics. During prototyping, performance and durability tests are conducted, while final assembly includes thorough verification according to safety standards PN-EN ISO 10218-1/-2 and FAT (Factory Acceptance Test) and SAT (Site Acceptance Test) procedures at the client’s site.

Key process stages:

3D modeling and process simulation (SolidWorks, ABB RobotStudio)

Motion path optimization and tooling configuration

Prototyping and performance/durability tests

Assembly and compliance verification with PN-EN ISO 10218-1/-2

FAT/SAT testing and final acceptance

We utilize advanced CAD software, such as SolidWorks, to create detailed 3D models of workstations and components. For robot analysis and simulation, we use tools like ABB RobotStudio and Fanuc ROBOGUIDE. These programs enable us to validate reach, detect possible collisions, optimize motion paths, and precisely select end-of-arm tooling—such as pneumatic or vacuum grippers. These technologies guarantee efficient implementation and secure automation processes.

Key tools and software:

CAD: SolidWorks

Simulation: ABB RobotStudio, Fanuc ROBOGUIDE

Reach analysis, collision detection, path optimization

End-of-arm tooling selection: pneumatic, vacuum grippers

Our team of specialists carefully selects components and materials based on key technological criteria and the specifics of each application. Ensuring precise positioning—such as ±0.02 mm for laser applications—is a priority, as is resistance to dynamic loads and compatibility with the operating environment, like meeting the IP67 protection class. We also consider the required mean time between failures (MTBF over 50,000 hours), and if needed, modify the design by choosing different structural materials—for example, using S355J2 steel instead of aluminum 6061 for increased rigidity.

Key selection criteria:

Required positioning accuracy (e.g. ±0.02 mm)

Dynamic loads and work environment (IP67 class)

Expected MTBF (> 50,000 hours)

Individual material selection or substitution based on application

Yes, MDP Engineering places particular emphasis on future scalability and flexibility in all workstation designs. Each installation is conceived to allow easy expansion, making it simple for the client to integrate new robots, functions, or tools as production needs evolve. We use modular systems and open communication interfaces, enabling rapid adaptation to changing technological and business requirements. This approach ensures that every automation investment retains long-term value and can be efficiently upgraded in the future.

Key advantages of our approach:

Readiness for expansion and modification

Easy integration of new robots, functions, tools

Modular systems and open communication interfaces

High flexibility and long-term investment value

Collaboration with MDP Engineering on implementing robotic workstations begins with a detailed analysis of production processes and identifying the client’s key requirements. The next step involves a preliminary technological audit to assess the automation potential and highlight core areas for improvement. Based on these findings, we prepare an implementation concept, a detailed project quotation, and a realization schedule, providing comprehensive support from initial design through commissioning and integration within the production line.

Key cooperation steps:

Production process analysis

Needs definition and technological audit

Preparation of concept and pricing

Realization schedule planning

Complete implementation and integration