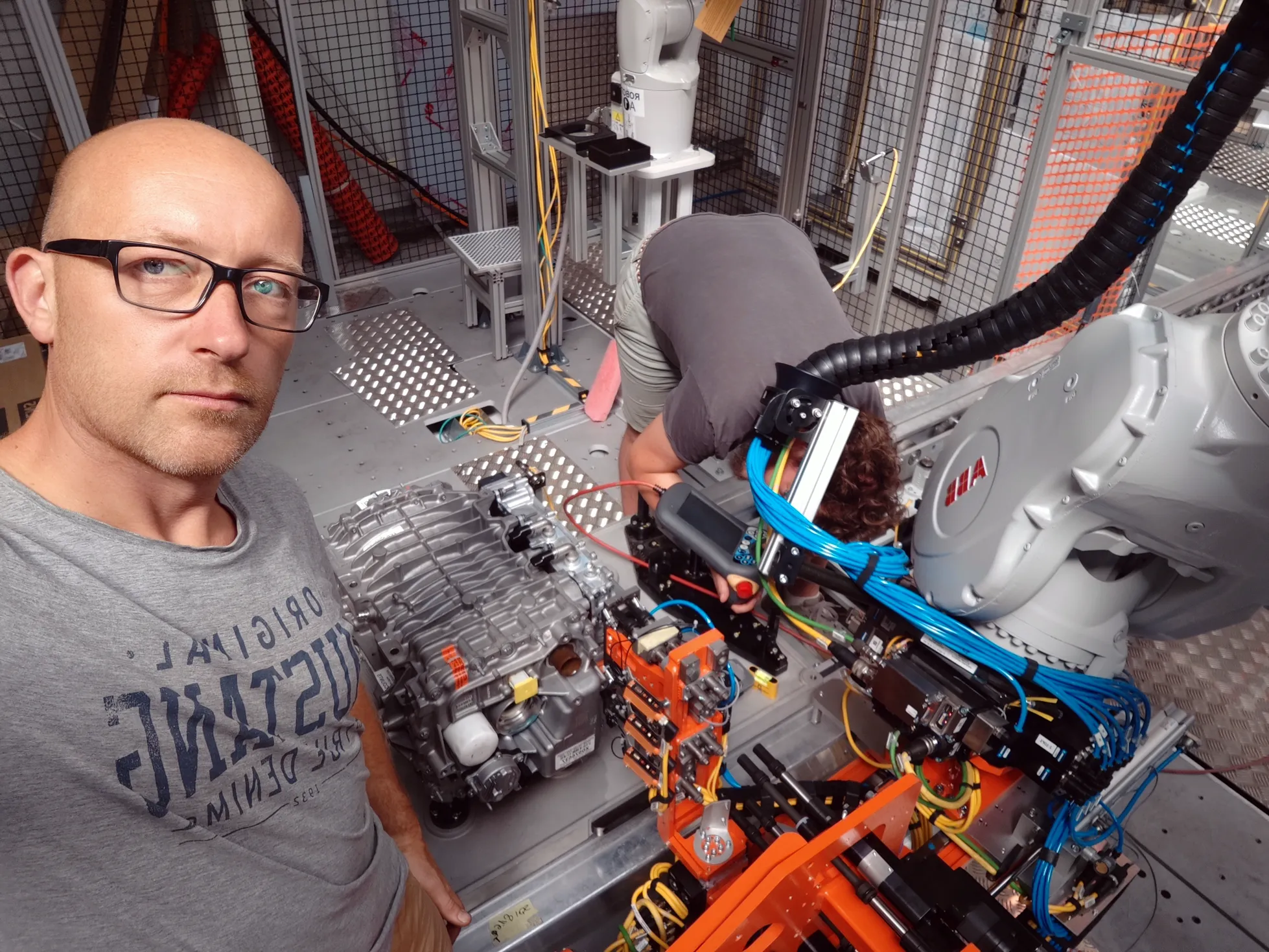

MDP Engineering specializes in creating optimized solutions for production lines—from needs analysis and design to system integration and commissioning. We combine years of experience in control system design with a phased technological startup methodology, ensuring cost and time efficiency while maintaining top safety standards.

Contemporary industry requires the integration of advanced industrial automation solutions with precisely planned commissioning processes. Automation and commissioning are the pillars of modern production engineering, enabling the creation of intelligent, self-regulating systems and their effective implementation in operation.

What Is Industrial Automation?

Industrial automation replaces human intervention in production processes with control systems based on algorithms, sensors, and actuators. At its core are programmable logic controllers (PLCs), which convert sensor signals (e.g., from encoders or thermocouples) into commands for actuators (motors, valves, cylinders).

MDP Engineering expands this definition to include:

- SCADA systems for process visualization and supervision

- Industrial networks (PROFINET, EtherCAT) for device communication

- Industrial robots tailored to specific production needs

Commissioning Process Stages

Commissioning a production line involves synchronizing mechanical, electrical, and programming expertise. Our approach includes:

- Technical documentation verification (compliance with PN-EN ISO 13849-1)

- Functional tests of individual modules using process simulators.

- System integration with the validation of communication protocols.

- Trial run with generating FMEA (Failure Mode and Effects Analysis) reports.

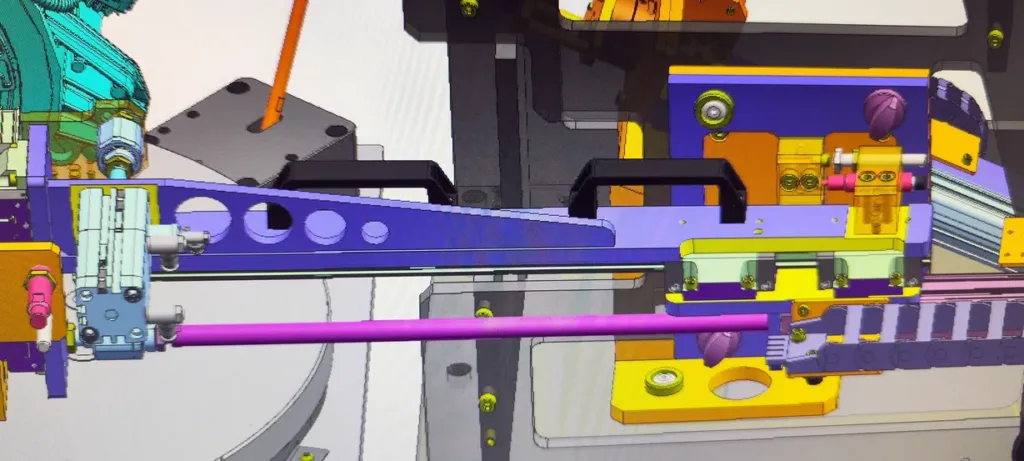

Automation System Design

Control Architecture for Production Lines:

At MDP Engineering, we use a hierarchical control model that divides the system into three layers.

Design and Simulation Tools:

Symulacje CFD (Computational Fluid Dynamics) pozwalają nam optymalizować układy chłodzenia w maszynach specjalizowanych, redukując zużycie energii o 15-18%.

Implementation and Commissioning of Systems:

Step-by-Step Start-Up Methodology

Our commissioning process is based on the V-Model philosophy, where each design phase corresponds to a dedicated testing stage:

From verifying individual functions, through module-level tests, to the launch of the complete solution. This approach allows us to detect potential errors at early stages, ensuring that the entire implementation runs smoothly, predictably, and without surprises.

FAT (Factory Acceptance Test)

Functional verification under laboratory conditions.

SAT (Site Acceptance Test)

Performance testing at the target location.

Cold Start

Operation with dummy products.

Hot Start

Full production with KPI monitoring.

Automation and Commissioning are services focused on the design, implementation, and start-up of production line automation systems.

The process includes needs analysis, integration of machines and PLC controllers, installation, and system configuration.

The goal is to increase production efficiency, reduce costs, and ensure compliance with standards.

Training and technical support are offered for users of new systems.

Risk Management during Deployment

Load tests

Using moment amplifiers up to 250% of nominal values.

Mapping bottlenecks

Through discrete simulations (Digital Twin technology).

Emergency procedures

With automatic safe stop sequences (Safe Torque Off).

Risk analysis at MDP Engineering includes:

In a project for the automotive industry, we implemented a predictive maintenance system based on bearing vibration analysis, reducing downtime by 40%.

We take pride in our long-term cooperation with our Clients, investing in relationships and long-term project support through:

EXPERIENCE

in the engineering industry

FLEXIBILITY

in the approach to the project

RESPONSIBILITY

for construction and design

IMPLEMENTATION

from idea to execution

The integration of industrial automation with a methodically planned commissioning process is the key to competitiveness in today's industry.

MDP Engineering's experience shows that applying a systemic approach (from 3D modeling to process validation) can reduce implementation time by 30–45% while simultaneously increasing the reliability of production lines.

Examples of implementation:

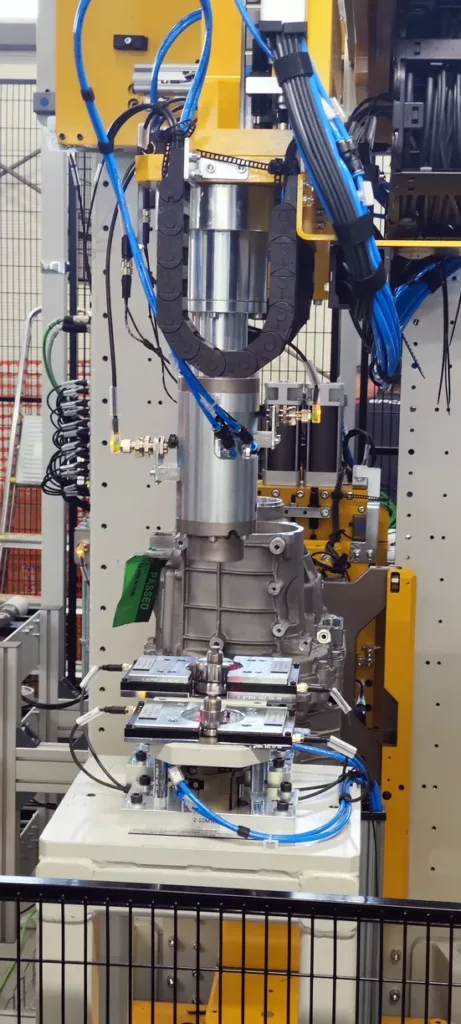

Integration of Welding Robots in the Metal Industry

For a client in the steel construction sector, we implemented:

3 six-axis KUKA KR 1000 robots with laser heads,

A vision system for automatic weld path correction,

Quality monitoring through spectral analysis of the welding arc.

Result: An 18% increase in productivity combined with a 12% reduction in welding wire consumption.

Packaging Line Automation in the Food Industry

The project included:

A palletizing station with a delta robot operating at up to 120 cycles/min,

A weight control system with ±0.5 g accuracy,

Integration with the ERP system via an OPC UA interface.

Result: Reduction of production format changeover time from 45 to 8 minutes.

We recommend a phased implementation of solutions:

Technological audit with identification of critical process points.

Pilot implementation in a selected production area.

Personnel training including organizational changes.

Continuous monitoring using predictive analytics.