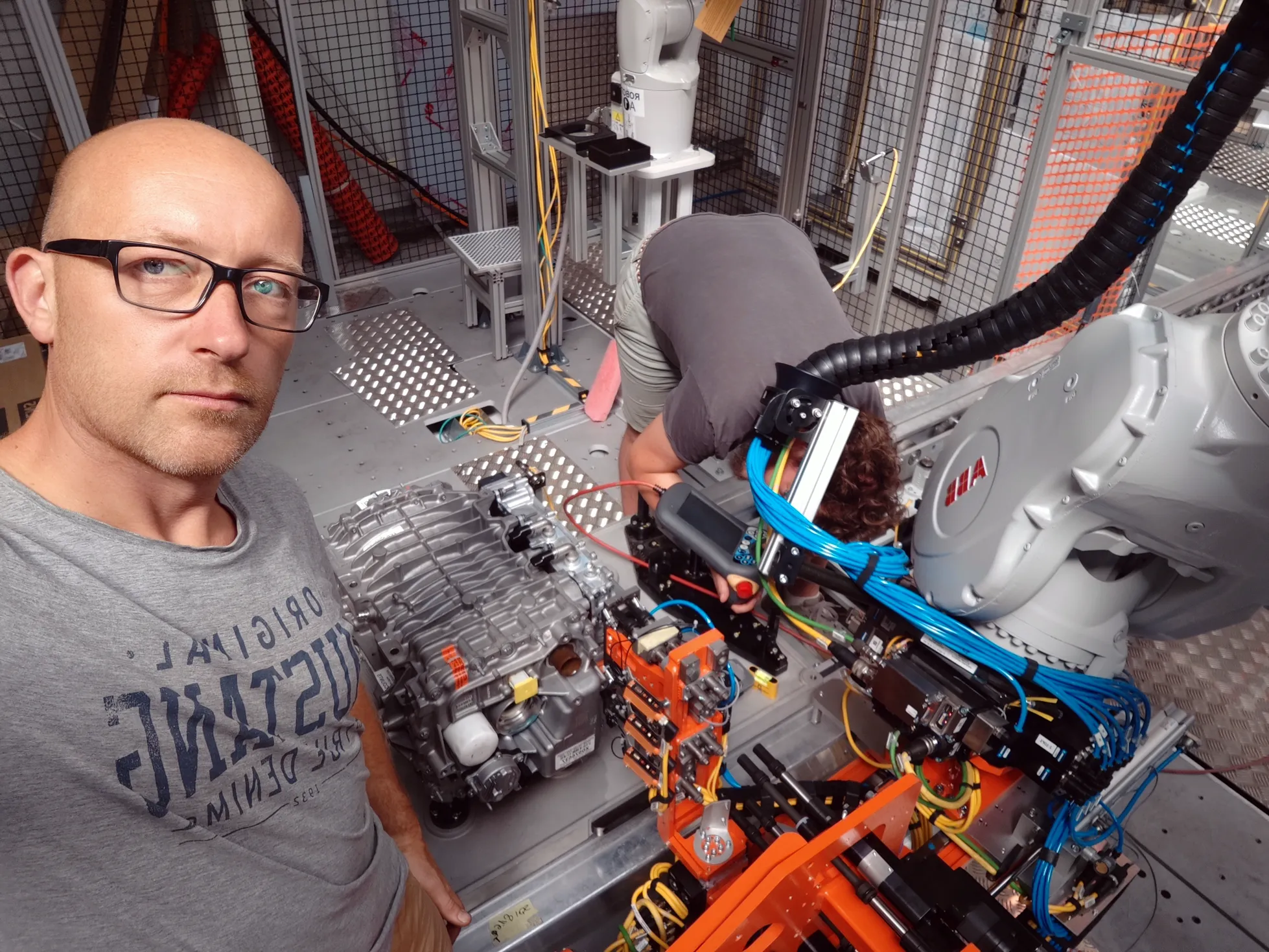

MDP Engineering delivers full-scale automation and commissioning services for production systems, enabling the implementation of robust, self-regulating manufacturing environments.

Contemporary industry requires the integration of advanced industrial automation solutions with precisely planned commissioning processes. Automation and commissioning are the pillars of modern production engineering, enabling the creation of intelligent, self-regulating systems and their effective implementation in operation.

What Is Industrial Automation?

Industrial automation replaces human intervention in production processes with control systems based on algorithms, sensors, and actuators. At its core are programmable logic controllers (PLCs), which convert sensor signals (e.g., from encoders or thermocouples) into commands for actuators (motors, valves, cylinders).

MDP Engineering expands this definition to include:

- SCADA systems for process visualization and supervision

- Industrial networks (PROFINET, EtherCAT) for device communication

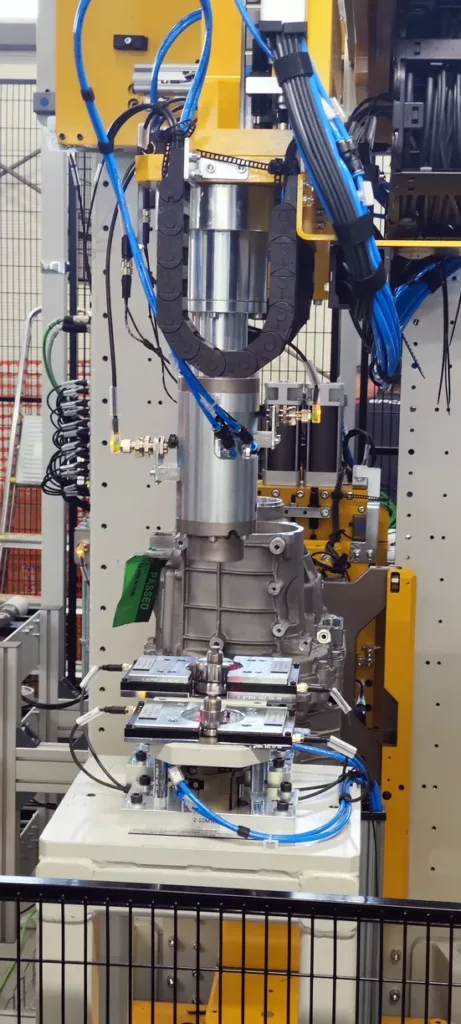

- Industrial robots tailored to specific production needs

Commissioning Process Stages

Commissioning a production line involves synchronizing mechanical, electrical, and programming expertise. Our approach includes:

- Technical documentation verification (compliance with PN-EN ISO 13849-1)

- Functional tests of individual modules using process simulators.

- System integration with the validation of communication protocols.

- Trial run with generating FMEA (Failure Mode and Effects Analysis) reports.

Automation System Design

Control Architecture for Production Lines:

At MDP Engineering, we use a hierarchical control model that divides the system into three layers.

Design and Simulation Tools:

Symulacje CFD (Computational Fluid Dynamics) pozwalają nam optymalizować układy chłodzenia w maszynach specjalizowanych, redukując zużycie energii o 15-18%.

Implementation and Commissioning of Systems:

Step-by-Step Start-Up Methodology

Our commissioning process is based on the V-Model philosophy, where each design phase corresponds to a dedicated testing stage:

From verifying individual functions, through module-level tests, to the launch of the complete solution. This approach allows us to detect potential errors at early stages, ensuring that the entire implementation runs smoothly, predictably, and without surprises.

FAT (Factory Acceptance Test)

Functional verification under laboratory conditions.

SAT (Site Acceptance Test)

Performance testing at the target location.

Cold Start

Operation with dummy products.

Hot Start

Full production with KPI monitoring.

Automation and Commissioning are services focused on the design, implementation, and start-up of production line automation systems.

The process includes needs analysis, integration of machines and PLC controllers, installation, and system configuration.

The goal is to increase production efficiency, reduce costs, and ensure compliance with standards.

Training and technical support are offered for users of new systems.

Risk Management during Deployment

Load tests

Using moment amplifiers up to 250% of nominal values.

Mapping bottlenecks

Through discrete simulations (Digital Twin technology).

Emergency procedures

With automatic safe stop sequences (Safe Torque Off).

Risk analysis at MDP Engineering includes:

In a project for the automotive industry, we implemented a predictive maintenance system based on bearing vibration analysis, reducing downtime by 40%.

We take pride in our long-term cooperation with our Clients, investing in relationships and long-term project support through:

EXPERIENCE

in the engineering industry

FLEXIBILITY

in the approach to the project

RESPONSIBILITY

for construction and design

IMPLEMENTATION

from idea to execution

The integration of industrial automation with a methodically planned commissioning process is the key to competitiveness in today’s industry.

MDP Engineering’s experience shows that applying a systemic approach (from 3D modeling to process validation) can reduce implementation time by 30–45% while simultaneously increasing the reliability of production lines.

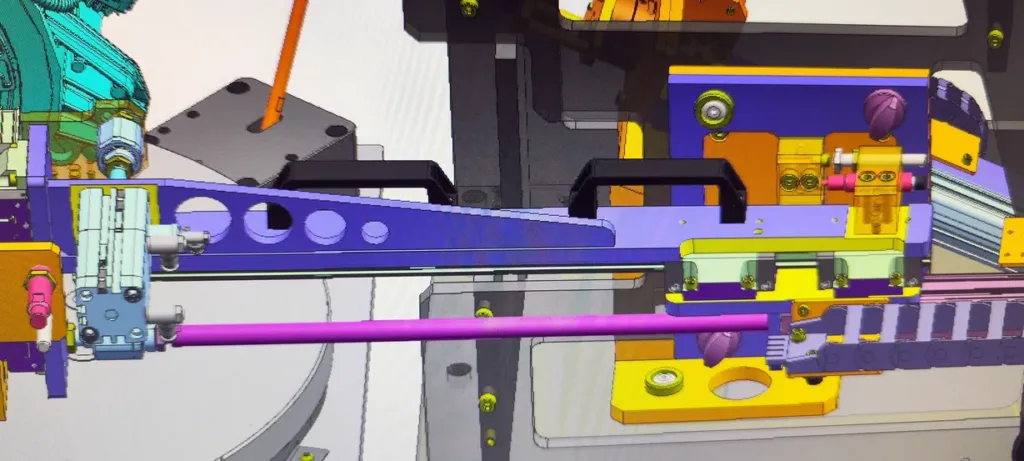

MDP Engineering uses a suite of modern design, simulation, and commissioning tools that ensure precision and high efficiency of all projects. For 3D design, we use advanced CAD software (SolidWorks), and for simulation and programming of automation and robotics systems, tools like Siemens TIA Portal, EPLAN, ABB RobotStudio, and Fanuc ROBOGUIDE. The implementation process is supported by data analysis tools, SCADA system monitoring, as well as FAT/SAT testing—all of which ensure project delivery according to the client’s requirements and international standards.

Core tools used by the company:

CAD software: SolidWorks

Simulation and programming tools: TIA Portal, EPLAN, ABB RobotStudio, Fanuc ROBOGUIDE

Monitoring and data analysis systems: SCADA, data acquisition and visualization tools

FAT/SAT testing and commissioning tools

According to MDP Engineering, industrial automation means comprehensive technological systems that support and streamline production at every stage. It includes not only advanced control of machines and lines, but also the integration of robots, quality measurement, data registration, remote monitoring, and performance analysis. Our approach combines reliable hardware solutions with modern software, resulting in higher efficiency, safety, and production flexibility in a rapidly changing market environment.

Key features of MDP industrial automation:

Comprehensive control of equipment and production lines

Integration of robots, quality, and measurement systems

Centralized monitoring and real-time data analytics

Increased efficiency, safety, and scalability of production

The commissioning process of a new production line begins with comprehensive project planning and analysis of technological and logistical requirements. We develop a detailed installation schedule, manage equipment deliveries, assemble modules, and integrate automation systems. After assembly, we carry out functional tests and trial production to verify performance and compliance with expectations. The entire procedure concludes with staff training and handing over technical documentation, ensuring a safe start and rapid achievement of full efficiency.

Key commissioning stages:

Project planning and requirements analysis

Equipment installation and automation integration

Functional tests and pilot production

Staff training and documentation delivery

Start-up and service support

MDP Engineering designs modern, modular industrial automation architectures tailored to clients’ individual needs and production line requirements. Our solutions employ a hierarchy of PLC controllers, SCADA systems, and distributed input/output modules, enabling flexible integration of new devices and easy system expansion. We utilize open communication protocols (such as Profinet and EtherCAT), ensuring data security, reliable transmission, and effective real-time management and monitoring of production processes.

Key architecture features:

Modular and scalable system structure

PLC controllers, SCADA, distributed IO

Open communication protocols (Profinet, EtherCAT)

Device integration and expansion

Real-time production monitoring and management

MDP Engineering applies multi-stage safety procedures during the commissioning of new automation systems and robotic workstations. We conduct detailed risk analysis and emergency scenario simulations, then implement dedicated technical solutions: multi-level safety systems, protective barriers, and real-time operation monitoring. Additionally, staff are trained and comprehensive functional tests are conducted, minimizing errors and ensuring compliance with PN-EN ISO and IEC standards. This approach ensures safe rollouts and an operator team that is well prepared for any operational eventuality.

Key safety and risk management elements:

Risk analysis and emergency simulations

Safety systems and protective barriers

Real-time operation monitoring

Staff training and functional testing

Compliance with PN-EN ISO and IEC standards

Yes, MDP Engineering provides dedicated modules and complete integration systems that enable robots to work with vision-based quality control and measurement devices. We implement solutions for automatic defect detection, geometric measurement, and component recognition during production. Our integration relies on industrial cameras, sensors, and specialized software, delivering reliable quality monitoring directly within the production cycle. This approach ensures high repeatability and enables errors to be eliminated at an early stage of the process.

Key integration solutions:

Vision quality control modules

Automatic defect detection

Non-operator-based measurement and identification of components

Full integration with production line and management systems

The cooperation process begins with a joint analysis of production requirements, during which we identify the key areas in need of automation or improvement. Then, we conduct a technological audit and prepare an initial solution concept, taking into account technical objectives, budget constraints, and desired timelines. Based on this, we prepare a detailed offer that includes the scope of work, proposed implementation schedule, and full engineering support at every stage—from project design to commissioning and staff training.

Key steps to start cooperation:

Analysis of production requirements and automation priorities

Technological audit and solution concept preparation

Precise cost estimation and implementation timeline

Comprehensive engineering support throughout the process

Examples of implementation:

Integration of Welding Robots in the Metal Industry

For a client in the steel construction sector, we implemented:

3 six-axis KUKA KR 1000 robots with laser heads,

A vision system for automatic weld path correction,

Quality monitoring through spectral analysis of the welding arc.

Result: An 18% increase in productivity combined with a 12% reduction in welding wire consumption.

Packaging Line Automation in the Food Industry

The project included:

A palletizing station with a delta robot operating at up to 120 cycles/min,

A weight control system with ±0.5 g accuracy,

Integration with the ERP system via an OPC UA interface.

Result: Reduction of production format changeover time from 45 to 8 minutes.

We recommend a phased implementation of solutions:

Technological audit with identification of critical process points.

Pilot implementation in a selected production area.

Personnel training including organizational changes.

Continuous monitoring using predictive analytics.